Fill & Finish

Completing the bioproduction process

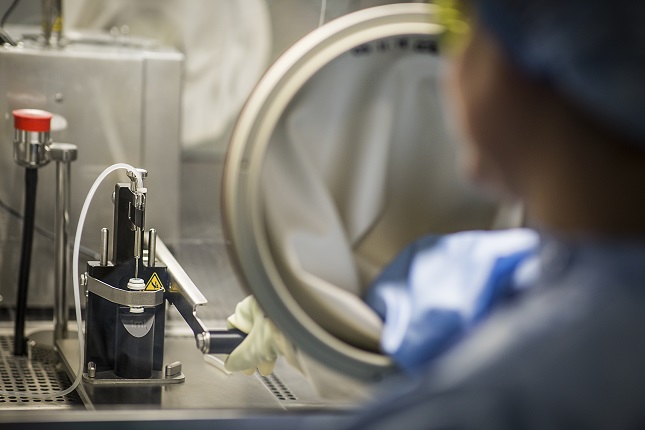

To complete our bioprocesses and create drug products, the Yposkesi facility is equipped with two cGMP Fill & Finish suites. Key elements about our fill & finish suites:

- Validated, aseptic and semi-automated;

- Equipped with a state-of-the-art grade A containment isolator;

- Total capacity of 12,000 vials per year;

- Vials are 100% tested for container closure integrity and visual inspection is performed before primary labeling;

- A variety of vial filling formats are available, including:

- Crystal© Closed Vial Technology (Cyclo-Olefin Co-polymer);

- Iso2R Glass vials

- To help you save more units for the patients, a variety of vial sizes are available;

- Perform AAV and lentivirus sterile filtration;

- All the filling processes are single-use;

Our platforms are equipped with the filling formats previously stated, but flexibility is key at Yposkesi! If you are looking for something different, do not hesitate to contact us to talk about your project!

Because we are a one-stop shop, our goal is to be your partner from process development up to commercial products. Therefore we are currently investing in the construction of a new building. This additional manufacturing facility will double our global manufacturing footprint and allow us to increase our capabilities to keep on reducing time to patients for your gene therapies.

Also located in the South of Paris, across the street from the current facility, this extension of our facility is designed for large-scale clinical and commercial batches. With commissioning in 2024, it’s designed to be certified (European Medicines Agency) EMA and Food and Drug Administration (FDA) compliant.