Analytical Development, Qualification & Validation - QC & QA

Quality is integral to Yposkesi’s principles

Key Elements of Yposkesi’s Quality Methods include:

- Risk management: always having the patient in mind, we have developed reliable and robust methods, according to Analytical Quality by Design (AQbD) and designed to be fully EMA and FDA compliant;

- Support: with extensive expertise, we can develop with our partners a choice of appropriate assays and provide support for the Chemical, Manufacturing, and Controls (CMC) requirements;

- In-house: 95% of analytical tests are performed in-house and an external network is well-established for specialized testing.

|

Platform assays:

|

AAV specific assays:

Lentiviral specific assays:

|

Text

|

Product specific assays:

|

In development:

|

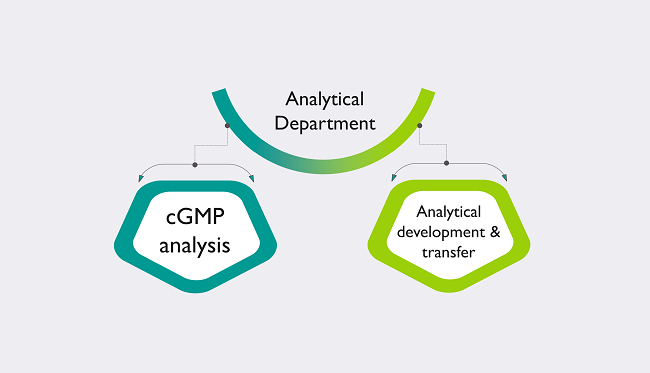

Our Analytical capacity is shared across two teams:

- current Good Manufacturing Practices (cGMP) analysis within the cGMP Quality Controls (QC) Lab team;

- Analytical development and transfer, testing for non-cGMP and Pilot scale batches, plus method validation at the Analytical Expertise Center.

The cGMP QC team:

- Maintains the environmental monitoring testing program for all the classified areas, the Highly Purified Water (WFI) loop, and all other utilities. Those programs consist of routine microbiology assays, bioburden testing, endotoxin, TOC, conductivity, etc;

- Tests all incoming raw materials up to release for cGMP manufacturing;

- Performs in-process control and release assays on all manufactured products;

- Runs stability studies.

The testing of your products can be performed internally at the cGMP QC lab or at the labs of qualified sub-contractors, depending on the method, contact us for more details.

The Analytical Expertise Center:

- The Analytical Expertise Center centralizes all incoming methods, requests, or method assessments;

- Assesses all analytical methods related to a project (method development, transfer, qualification, validation, internal or external assay, etc.);

- Manages analytical development, transfer, and validation according to recipient lab needs;

- Ensures that methods used are fit for purpose and scientifically sound;

- Supports all analytical method trouble-shooting.

Test methods are qualified or validated according to product development phase and ICH Q2R1 requirements. As a minimum, the qualification assesses specificity, linearity, matrix interference, accuracy, and precision as applicable. Yposkesi is also routinely applying AQbD approaches to analytical method development, to ensure that our methods are developed to be robust and well-understood.